PORSCHE | Team Boards

Challenges

USE CASE OVERVIEW

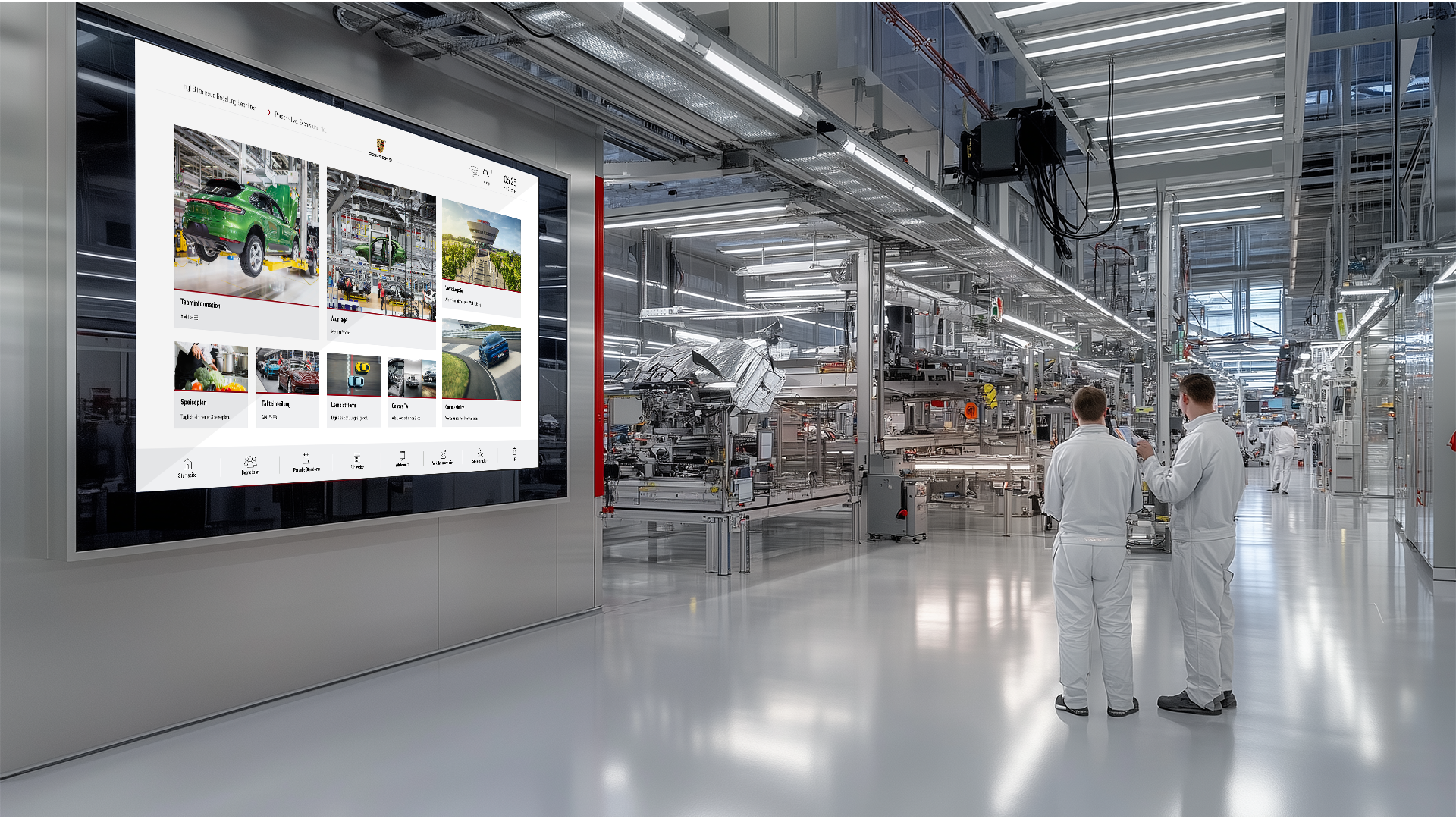

Since 2019, our headless CMS has been an indispensable part of the Porsche production landscape and is used on over 400 devices at the Leipzig, Zuffenhausen, Sachsenheim, Weissach, Hemmingen, Asperg, Ludwigsburg and Bietigheim sites. The introduction of the team boards at the sites has significantly optimised shop floor communication. Thanks to our headless CMS, it is possible to customise the boards for each location, allowing each location to respond individually to the site-specific challenges.

RESULTS

The digital information board acts as a living nerve centre for employees in Porsche’s production areas. It not only provides a wealth of information, but also creates an efficient communication platform. The information to be displayed varies from location to location; the boards are used for staff training, for example, but also as a simple communication tool for communicating shift schedules, among other things. The boards are mainly maintained by the company’s own employees, which means they can be customised quickly and easily.

STATUS QUO

Our CMS enables the centralised management and updating of content on the information boards, ensures consistent information distribution and thus contributes to efficiency and smooth production processes. The system specifically supports the operational shop floor management of the Porsche teams through a clear and standardised presentation of data such as cycle schedules, driving information, operational information, meal plans, personnel notifications and automotive production information as well as a meaningful KPI dashboard.

Five different information boards are currently available for our customers at five different locations. These have been adapted to site-specific requirements and are constantly optimised and updated in regular dialogue with customers.